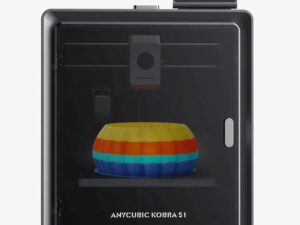

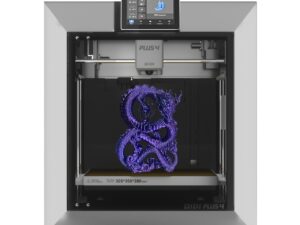

FDM printers

An FDM (Fused Deposition Modeling) printer, also known as a Fused Filament Fabrication (FFF) printer, is a type of 3D printer that builds objects layer by layer by extruding a thermoplastic filament. It’s one of the most common and accessible 3D printing technologies, often used for prototyping and general 3D printing needs.

Filter

Showing all 5 results

How it works:

FDM printers use a spool of plastic filament, which is melted and then extruded through a nozzle onto a heated build plate. The printer moves the nozzle across the X, Y, and Z axes to deposit thin layers of the melted plastic, building the object layer by layer. FDM printers can use a variety of thermoplastic filaments, including PLA (polylactic acid), ABS (acrylonitrile butadiene styrene), and PETG (polyethylene terephthalate glycol). FDM printers are popular for rapid prototyping, creating functional parts, and producing models for design and engineering. FDM printers are generally considered more affordable and accessible than other 3D printing technologies like SLA (Stereolithography) or SLS (Selective Laser Sintering). While affordable and accessible, FDM prints may not have the same level of detail, smoothness, or strength as prints from other technologies like SLA or SLS.